Process Management in Practice: When Efficiency Becomes a Competitiveness Factor Interim management is an innovative way of dealing with temporary shortage of middle and senior managers within the company.

-45cd1ce3.jpeg)

Process Management in Practice: When Efficiency Becomes a Competitiveness Factor

As a business leader, you are likely familiar with the question: what happens in the company while you are on vacation? Many find it difficult to let go of day-to-day operational tasks because they feel that without them, everything comes to a halt. Well-designed processes, however, not only take the burden off the leader, but also remain scalable as the company grows.

What is process management?

Every company’s goal is to turn its resources into valuable, marketable products or services. The series of repetitive activities required for this is called a business process. Process management, or Business Process Management (BPM), is the systematic identification, design, execution, measurement, control and continuous improvement of these processes in line with the organization’s strategic objectives.

The essence of the approach is not merely the application of technical tools, but the alignment of the organization’s business processes with its strategic goals. This strategic-level focus is what makes this mindset particularly valuable in today’s rapidly changing market environment.

The paradox of choice: how to choose a model?

When a business leader comes to realize that “in-my-head” or “this-is-how-we-usually-do-it” mechanisms are holding back growth, they often face a bewildering variety of process management models. BPM, Lean, Agile methodologies, OKR, Six Sigma – the list goes on. The most common mistake is looking for a single, seemingly ideal solution.

The reality is that there is no one-size-fits-all model for every company. The optimal system is always the one that fits the company’s current profile, organizational structure and operational characteristics. What works in a 10-person tech startup may no longer be effective in a 50-person trading company. The key is flexibility: as the company changes, the processes must evolve with it.

The evolution of process development in practice

Let’s look at how this plays out in practice through the example of a growing commercial SME.

In the initial phase of operations, in a 20-person company, processes largely rely on the knowledge of key people. “Zsuzsi knows who we can give a discount to.” The leader intervenes on a daily basis, and many decisions are made on a case-by-case basis. Although the system appears to function, errors are becoming more frequent. Duplicate orders, missed deadlines and complaints all signal that the model is unsustainable.

During the introduction of the first operational system, the company maps its three most critical processes in order to support growth: sales, order management and complaint handling. Standard templates and standardized steps are introduced, and weekly status meetings are held using a Kanban board. The most important step is clarifying responsibilities: every process gets an appointed owner who is accountable for its operation.

When the company expands with a new, project-based business line, the existing system is no longer sufficient. At this point, a hybrid model is introduced that combines the structured nature of BPM with the flexibility of agile methodologies. A common customer journey process is created, while performance is measured through specific KPIs, and continuous improvement is driven by Kaizen-style development meetings.

On the boundary between project and process thinking

One of the most common misunderstandings in corporate practice is the confusion between process management and project management. Project management focuses on achieving unique, one-off goals. In contrast, process management focuses on organizing recurring, ongoing activities efficiently.

Understanding the difference is crucial because the two areas require different methods, tools and metrics. Process design is centered on simplifying, standardizing and automating repetitive tasks.

Why is it worth investing in process improvement?

The numbers speak for themselves. Practical case studies show concrete, measurable results. At Grundfos Magyarország Gyártó Kft., for example, optimization of production processes reduced the average time of a critical operation from 73 minutes to 32 minutes, a 56% improvement. In the international case of Gousto, a process simulation solution resulted in a 13% improvement in station utilization.

This not only reduces costs, but also enables faster performance, higher quality and a better customer experience.

The tangible results of process control and optimization include shorter lead times, fewer errors, more economical use of resources and measurably better business performance. The key lies in establishing a mindset of continuous improvement.

The role of automation in modern process management

In the age of digital transformation, automation is no longer a luxury but a necessity. Automating repetitive, rule-based processes does not only bring cost efficiency, it also frees employees to focus on higher value-added tasks. Automatic execution is particularly quick to pay off in administrative processes.

For small and medium-sized enterprises, the most obvious entry point into automation is often the introduction of a CRM system. What does this mean in practice? A well-configured customer relationship management system automatically records customer interactions, sends reminders about follow-up tasks, and accelerates proposal preparation with standardized templates. The savings are substantial: in a 20–30-person trading company, this can save 1–2 hours of administrative time per salesperson per day. On a monthly basis, this frees up significant capacity for real customer work. But CRM is not the only opportunity. Automating invoicing processes, stock notifications or appointment booking systems can also be a popular solution with a quick return on investment.

Companies at the forefront of RPA (Robotic Process Automation) and AI-based process automation can achieve significant efficiency gains in certain processes. Successful automation, however, requires well-thought-out process design, precise requirement specifications and proper change management.

The added value of interim management in process optimization

Process improvement is typically a complex project that requires not only technical knowledge, but also experience and objectivity. This is where the role of interim management becomes particularly valuable. Interim experts map out problems with an outsider’s perspective and an unbiased attitude, and since they are not part of the organization’s long-term internal power structures, they remain free from in-house political influence.

The biggest difference between traditional consulting and the interim approach is its hands-on nature. While consultants perform analyses and make recommendations, the interim process manager embeds themselves in the company’s operations and personally implements the changes. This practical approach ensures that process optimization does not remain merely on paper.

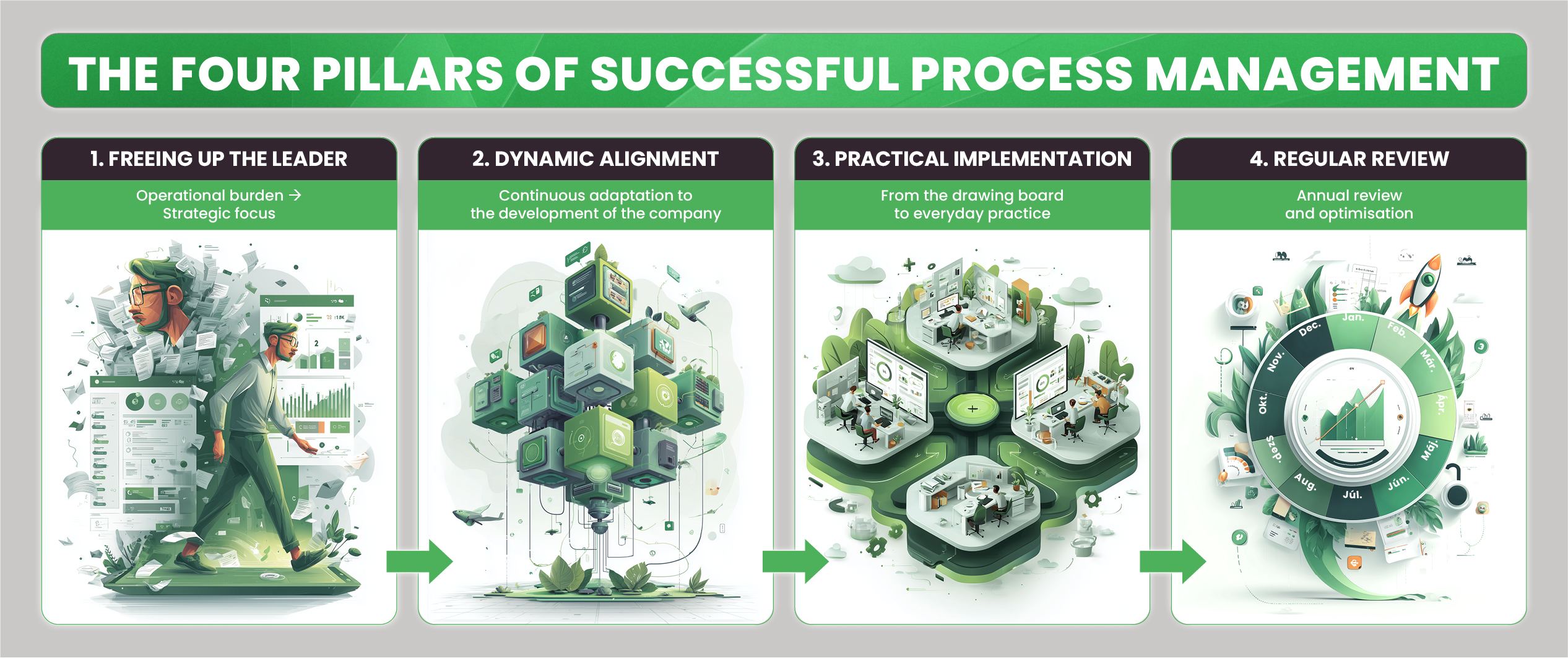

The four pillars of successful process management

Whatever model we choose, success depends on four key factors. First, freeing up the leader: good processes lift the burden of operational tasks off the leader’s shoulders, allowing them to focus on strategic directions and business development. Second, dynamic alignment: the system must always adapt to the company’s current size, maturity and objectives.

Third, practical implementation: the best system is worthless if it exists only on paper. It is essential to ensure that the designed processes become part of everyday practice. Fourth, regular review: at least once a year it is worth asking whether our current processes are still effectively serving our goals.

Change management as a critical success factor

Both the literature and practice show that the greatest barrier to process improvement is not technical but human: internal resistance. Conflicting interests and attachment to comfort zones often stall improvement initiatives.

The interim expert is particularly effective in this environment because they possess the objectivity and independence needed to enable meaningful simplification and optimization. This is especially important in situations where internal leaders are constrained politically or culturally.

The culture of continuous innovation and measurement

Effective process management is not a one-off project but an ongoing task. Successful organizations regularly review their processes, measure their performance based on specific indicators, and remain open to applying new methods and tools.

Defining KPIs, regularly measuring process performance, and establishing feedback loops are essential for continuous improvement. This approach ensures that the system truly serves strategic objectives and can adapt to a changing business environment.

Building an effective operating model is the result of deliberate planning. The goal is to create a system that brings stability and predictability while remaining flexible enough to adapt to changes in the market.

Interim Kft. has been providing interim management services in Hungary since 2003. Our experts support our clients’ process development efforts with the experience gained from more than 850 projects. If you are interested in how process improvement can become a competitive advantage in your company as well, our experts are at your disposal for a free consultation.